Accurate measurement instruments are crucial for safety and reliability in engineering and material science. Strain gauges have always been a fundamental tool for characterizing stresses in a range of materials. Knowledgeably using strain gauges, their functional mechanisms, and applications can elevate material testing, resulting in stronger and tougher structures. This article discusses how strain gauges measure stress and help in better material testing.

Understanding Strain Gauges

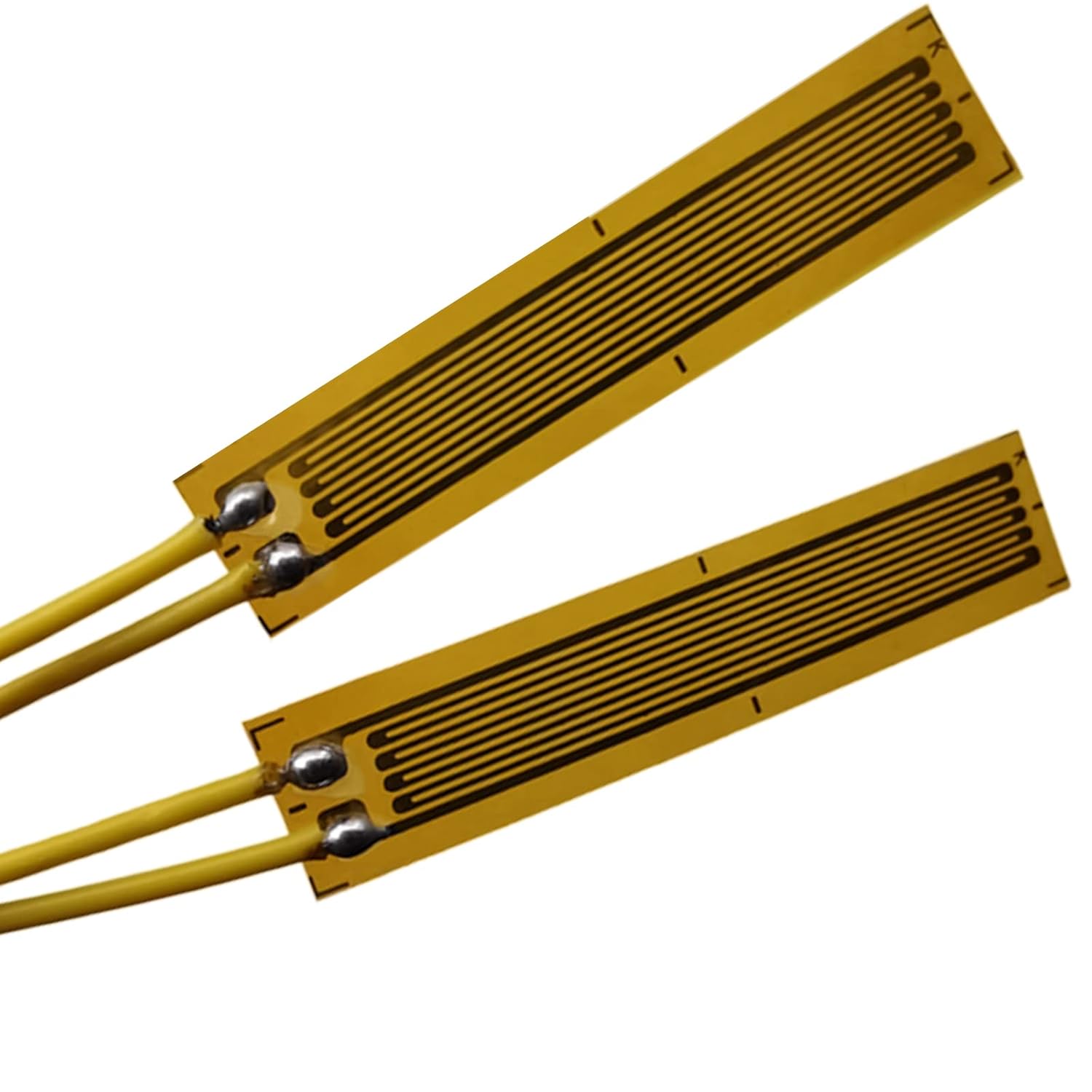

Strain gauges are miniature instruments that assess how much a material stretches or undergoes deformation. Usually made of a thin wire or foil in a grid formation, these devices are attached to the surface of materials. As the material deforms when a stress (force) is applied, the corresponding change in resistance can be directly related to precise deformation measurements.

The latest technology has made these devices more accurate and sensitive. Contemporary strain gauges are superbly delicate in identifying changes in material properties for an engineer or researcher. This is crucial in industries with high safety levels, like aerospace and civil engineering.

How Strain Gauges Work

The basic working principle of strain gauges is measuring electrical resistance. When the device is attached to a material, deformation changes its length and cross-sectional area, affecting the electrical resistivity inside the gauge. The strain on the material can be computed by detecting changes in resistance.

The Wheatstone bridge is an integral part of this process. This setup enables engineers to detect small changes in resistance with great accuracy. This change in resistance can be measured against a reference, and strain can be calculated accurately using this comparison. This technique ensures that even the most minor deformations are detected.

Applications in Material Testing

Strain gauges are extensively used in testing materials since structural integrity is of the utmost importance. Engineers affix strain gauges to different components to measure stresses during testing. This is especially useful for evaluating new materials and structures, as it provides a greater understanding of how materials respond to stress.

Strain gauges are frequently used in fatigue tests, where materials are subjected to repeated loading cycles to study their serviceability. Strain gauges identify weak spots and potential failure areas, allowing engineers to make modifications where necessary. This results in designs that are stronger and more resilient to real-world demands.

Strain gauges are used for fatigue and bonded plate testing and help us understand how materials behave in extreme conditions. Materials can be significantly affected by high temperatures, pressure, and other environmental factors. With strain gauges, engineers can track material responses, enabling them to design better solutions for maximum strength.

Benefits of Utilising Strain Gauges

The benefits make strain gauges an essential tool for material testing. One of the most compelling factors is the integration with IoT, which provides data in real time, allowing immediate response. This is valuable in dynamic testing environments, where fast decisions are needed.

In addition, strain gauges are accurate and precise, providing consistent results. Modern strain gauges come with technological enhancements and can detect minute changes, allowing engineers to make informed decisions based on accurate data.

Moreover, strain gauges have a wide range of uses. They can be used across many types of materials and structures. Whether metals or composites, these devices play a crucial role in understanding how different materials respond to stress. This versatility makes them invaluable across industries, from automotive to aerospace.

Conclusion

Strain gauges are reliable, repeatable tools for material testing. Their precise and accurate stress measurements increase our understanding of material behaviour under different conditions. Using strain gauges, engineers and researchers have developed more durable and dependable structures that respond effectively to real-world demands.

Using strain gauges has evolved throughout history, along with challenges and advancements. With ongoing technological improvements, these tools will play an even greater role in the future of engineering and material science.